The Greatest Guide To Window Infill Panels

Table of ContentsAll about Timber Frame Infill PanelsThe Only Guide to Metal Infill Panels6 Easy Facts About Double Glazed French Doors With Side Panels ShownThe Best Strategy To Use For Railing Infill PanelsSome Known Facts About Custom Double Pane Glass Panels.

Adhesives are not exempt. Composite spandrel/ infill panels that use flammable adhesives will require to be evaluated as a 'product' and achieve an item an EN 13501-1 item combustibility category of A2-s1, d0 or much better. Yes.

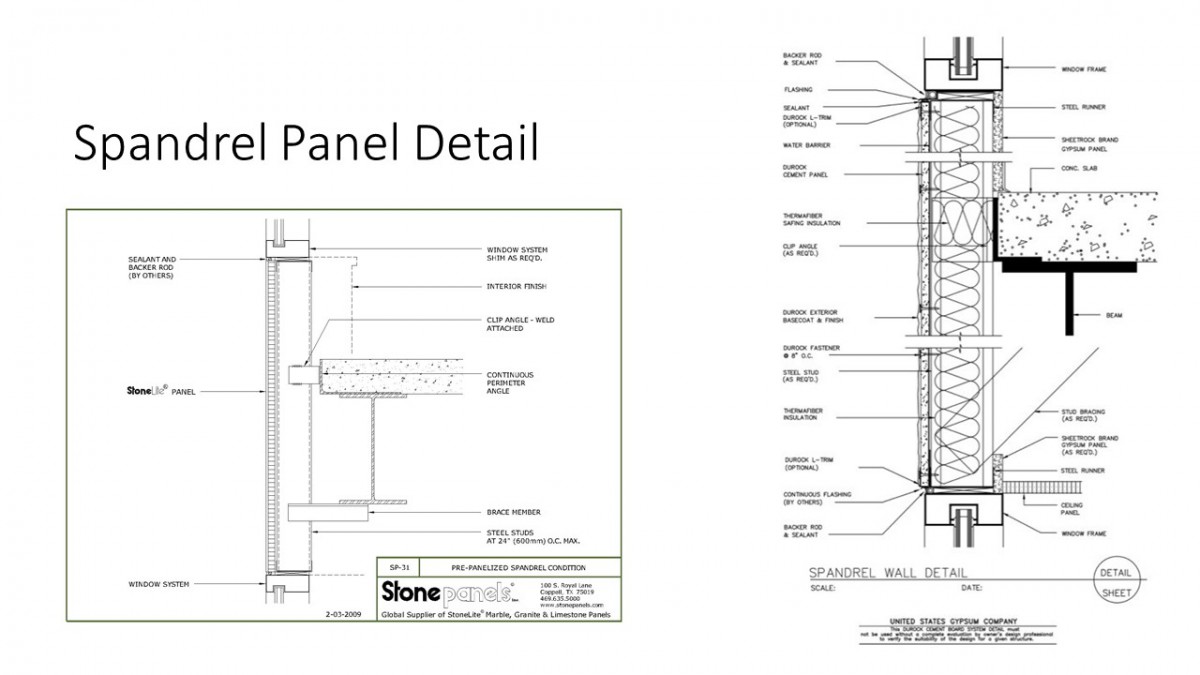

Opaque glazing, metal panels, MCM (metal composite products) panels, or insulated laminated panels are usually made use of as spandrel infill. When insulation is made use of inboard of the spandrel infill, an air area is regularly presented to prevent thermal damage to the spandrel infill. Unfortunately, the air area can supply a chance for condensation to form on the interior face of the spandrel infill.

Everything about Metal Infill Panels

Must badly created spandrel conditions be left unattended, condensation can result in moisture or visual damage to the spandrel panel and/or interior surfaces. When condensation kinds at the spandrel infill of a glazing system, numerous types of damage can take place, and the impacts of condensation can be far-reaching. In addition to wetness damage and microbial development, condensation development on spandrel infill can also have a negative impact.

This wetness can be soaked up by the surrounding components, triggering damage to the assembly and surrounding surface areas. As condensation establishes in these unventilated areas, microbial growth may establish and spread out to adjacent locations, causing more damage. Condensation accumulation in these areas can harm glazing spandrel coverings. In addition, mixes of these kinds of damage can happen, causing progressive damage that will require professional removal.

One way to postpone the formation of condensation on the glazing system spandrel infill is to utilize the building A/C system. By increasing air flow near these places, more heat will be transferred to the assembly and boost interior surface temperatures. Another way to make use of the HEATING AND COOLING system is by reducing the interior relative humidity set points with regard to outdoors temperature level.

The Of Window Infill Panels

Another method of discouraging condensation is by sealing the horizontal-to-vertical mullion joints at the spandrel cavity to avoid uncontrolled air migration into the cavity. Generally, an unchecked interior is moisture laden and when it enters contact with the spandrel infill, which is below the humidity, it increases the amount of condensation development. This can be accomplished by increasing the thickness of one of the lites of glass or by incorporating a laminated layer of glass with a noise-reducing interlayer, usually a polyvinyl butyral or PVB. Back pans are metal sheets, normally aluminum or galvanized steel, that are connected and sealed to the curtain wall framing around the boundary behind opaque areas of a drape wall.

Back pans provide a 2nd line of defense against water seepage for areas of the drape wall that are not visible from the interior and are challenging to access. Water infiltration in nontransparent areas can continue for extended time periods triggering significant damage prior to being found. Back pans likewise are to be chosen over foil vapor retarders in high performance and humidified structures as convection currents short-circuiting the insulation can trigger condensation, moistening and eventually failure of these spandrel areas.

All about Timber Infill Panels

Mindful detailing can supply a technique to thermally separate the cavity from the interior - window infill panels. An interior back pan behind the insulation is desirable also, to avoid condensation on the metal shadow box from the interior. Drape wall systems should move back to flooring structure or intermediate framing both their own dead load plus any live loads, which consist mainly of positive and unfavorable wind loads however may likewise consist of a snow load applied to big horizontal locations, seismic loads, maintenance loads and others.

Therefore the connections to anchor the drape wall must be created to allow differential movement while withstanding the loads applied. In stick-framed aluminum drape wall, vertical mullions frequently run previous two floorings, with a combined gravity/lateral anchor at one floor and a lateral anchor just at the other. The splice in between the vertical mullions will likewise be designed to permit vertical movement while offering lateral resistance. custom double pane glass panels.

Keep in mind that this movement slightly distorts the anchors at the vertical mullions. Specific units pop over to this web-site of glass need to accommodate the motion of the surrounding aluminum frame by sliding along glazing gaskets, misshaping the gaskets or a mix of both. The movement of the glass within the frame and the motion required in the anchors tend to cause additional stresses into a stick framed system.

Because these systems are regularly customized designed, the amount of motion to be accommodated can be thoroughly engineered into the system. Anchoring of unitized drape wall normally consists of an exclusive assembly with three-way dimensional adjustability. The anchors happen at each set of vertical mullions along the edge of slab or spandrel beam.

Metal Infill Panels for Beginners

The stack joint is developed to resist lateral loads while the two floor anchors withstand gravity and lateral loads. Among the two flooring anchors will enable motion in airplane with the unitized system. Fire safing and smoke seal at gaps between the flooring slab-edge and the back of the curtain wall are important to separate in between floorings and slow down the passage of fire and combustion gases between floors.

Laboratory-tested fire ranked assemblies might be required in unsprinklered structures by some codes as Perimeter Fire Containment Systems when the floor assemblies are needed to be fire-resistance rated. The rankings of the Border Fire Containment System must be equal to or greater than the flooring score. These systems supply confidence that the Extra resources materials utilized for border containment remain in location for the defined duration of the needed ranking in a fire occasion.